Bucher Vaslin is entering the market for de-alcoholisation on an industrial scale.

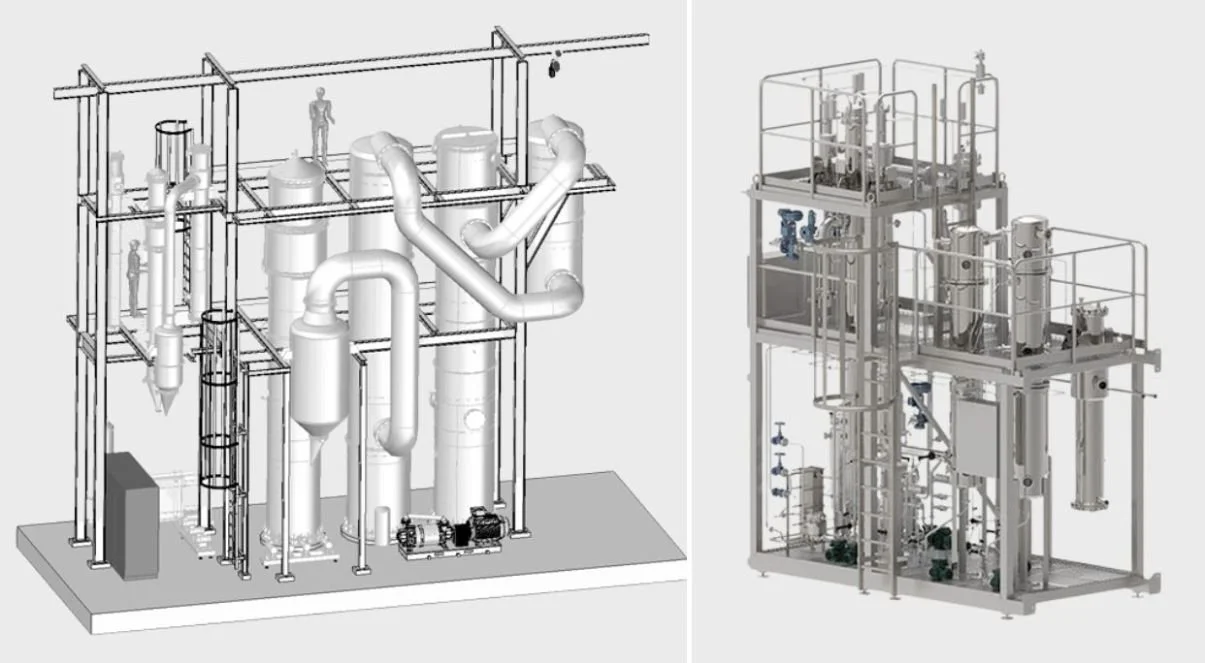

The solution offered, developed by Bucher Unipektin, is based on low-temperature vacuum evaporation technology (39°C). Lexy De-Alconox is a variation on the units marketed for 30 years by Bucher Unipektin for fruit juice concentration. These units can process cloudy products while ensuring optimal energy efficiency and reduced maintenance. Dealcoholisation is carried out continuously and enables the production of non-alcoholic beverages and wines (<0.5%).

Available in four models ranging from 15 to 200 hl/hour, Lexy De-Alconox meets the growing demand for low-alcohol beverages with a solution that allows alcohol to be separated at low temperatures.

Contact us for more info on our range of de-alc solutions for your winery